GRAY WATER RECYCLING

The way to use twice the water we buy

There is currently no single, explicit and globally accepted definition of gray water.

European standard 12056-1 defines gray water as wastewater with a low level of pollution such as produced by showers, bathtubs, sinks and washing machines and which can be recycled as non-potable cold water.

On the other hand, kitchen wastewater is excluded due to the high level of fat and food waste it contains.

The use of gray water, such as the use of rainwater or well water, is an effective way to reduce the consumption of potable water consumed in buildings, to protect the environment and lower the costs of water consumption. In addition, less wastewater is produced as a result of gray water recycling, as the water is used twice, resulting in additional ecological and economic gain.

Recycling gray water in residential and tertiary buildings as well as hotels is a judicious way to save drinking water and reduce wastewater discharges, also offering an ideal way to obtain the best levels of environmental certifications, in order to meet the criteria of sustainable construction.

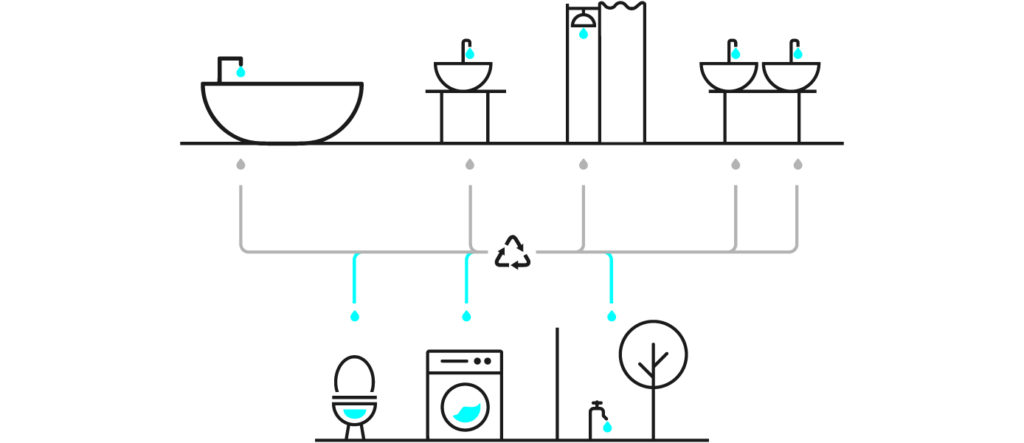

Gray water recycling essentially involves collecting the water used for body hygiene (shower, bath, sink) in a system designed for this purpose (gray water recycling system).

Drinking water supplied to the house is therefore used a second time (as non-drinkable cold water).

There are various technical approaches to recycling gray water.

- Technologies differ considerably in their complexity, size, recycling performance and recycling quality.

There are direct-use systems, retention systems as well as physical, chemical, biological and biomechanical systems. Comparative studies have shown that membrane bioreactors (MBR) currently represent the best technology for recycling gray water thanks to their exceptional cleaning performance.

- Our system AQUACLEAR, using MBR technology also possesses the advantage of requiring little space and guarantees stable quality parameters even if the effluent inlet characteristics fluctuate, which means that the requirements of the European directive regarding the quality of bathing water are always respected

Download our brochure

Recycling

AQUACLEAR

To bury outside

Our system AQUACLEAR using NEOPHIL® membrane technology recycles domestic gray water in a three-step process. Screening allows coarse materials to be stopped before the collected gray water is stored.

The gray water is then biologically pre-cleaned by natural bacteria favored by aeration.

Ultra-filtering NEOPHIL® membrane filtration provides total protection against the passage of bacteria and provides 99.999% protection against the smallest viruses.

The non-potable cold water derived from this process then feeds the points of consumption using a booster and can be used to supply the reservoirs, the toilets, the washing machine, the sprinkler, as well as for the cleaning of surfaces.

If there is not enough treated gray water available in the last tank, the system can be automatically supplied with potable water, or even rainwater. The system range AQUACLEAR, allows the daily treatment of volumes of gray water of 1 L and over several ten m500, made available for uses of non-potable cold water.

All the processes are monitored by an automatic device, ensuring optimal water treatment.

The compact systems are integrated into a tank assembly which can be installed inside the building in the basement.

All the processes are monitored by an automatic device, ensuring optimal water treatment. The compact systems are integrated into a tank assembly which can be installed inside the building in the basement.

The whole system is supervised thanks to the control of each phase of the process.

All parameters can be adjusted individually even when absent, and the stored water maintains the necessary quality.

The volume of the tanks depends on the volume of gray water treated.

The overpressure system is installed at the outlet of the buffer tank. Our system AQUACLEAR can be installed both in the context of new construction and renovation.

* AQUACLEAR recycling systems can be combined with a rainwater recovery system from inaccessible roofs. The latter must of course comply with all the criteria relating to the regulations of August 21, 2008 (DEVO0773410A).

The connection of the two systems will be made at the level of the service water tank.

In the event of a lack of filtered gray water, a pump placed in the rainwater tank will transfer the quantity necessary to ensure the continuity of the service water supply, before using drinking water.

The advantages of the AQUACLEAR® system

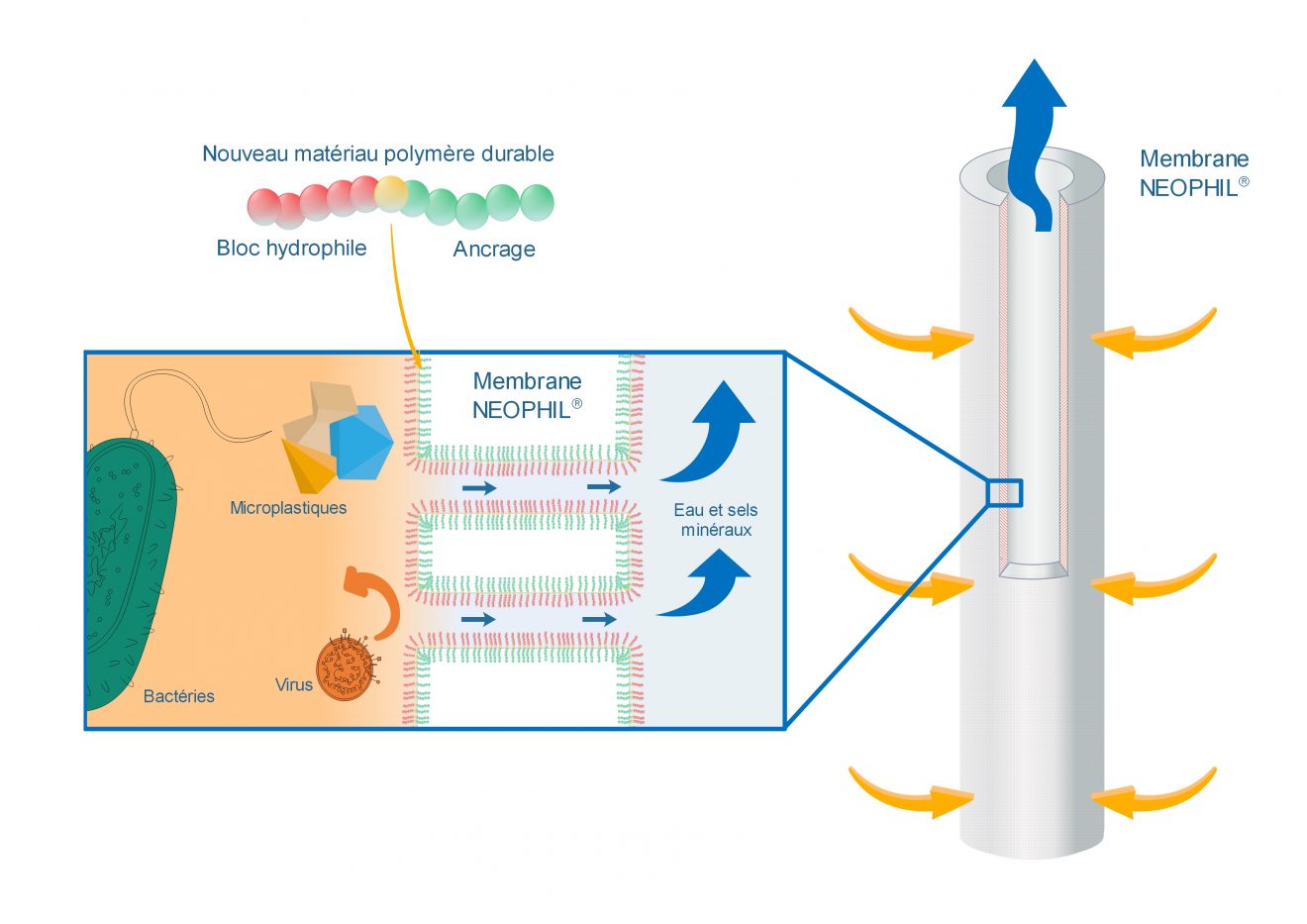

The heart of the system: new generation NEOPHIL® membranes with exceptional performance.

- Resistance to oxidants (chlorine, ozone, etc.)

- Excellent mechanical resistance

- High hydrophilicity new and old membranes

- Permanence of the hydrophilicity of NEOPHIL® guaranteeing the control of energy expenditure and cleaning products over time

- Biodegradation resistance

- The stability of the porous structure ensures that performance is maintained and therefore a constant virus retention rate:

VIRUS reduction> 4 log on new membranes AND VIRUS reduction> 4 log on aged membranes (exposed to 200 ppm.h of chlorine)

Security:

- The membranes currently used on the market are membranes in the form of plates, which have a cut-off threshold (fineness of filtration) close to 40 nm (nanometer). NEOPHIL® membranes have a cut-off threshold (fineness of filtration) of 15 nm (nanometer). This size, almost 3 times smaller, is an incomparable guarantee of health safety, allowing 99,9% of viruses to be retained.

- The membrane design uses neither BPA nor BPS (Bisphenol A, bisphenol S)

Reliability:

- NEOPHIL membranes also used in wastewater treatment plants, under extremely restrictive conditions.

- Unlike the main MBR no clogging of the membrane as it is used.

- AQUACLEAR is the only system to have a regular backwashing system for the membranes, which provides unrivaled performance compared to other products on the market.

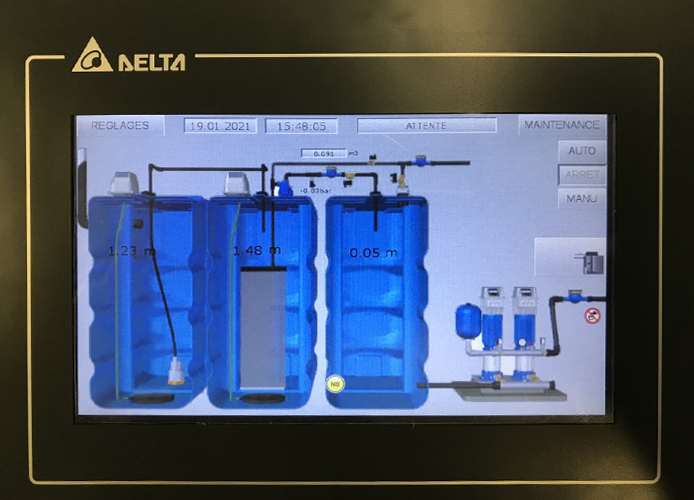

The command and control of the process.

The design of the box was based on two simple ideas:

Be simple to understand:

Thanks to a tactile supervision screen where the process is represented, and where the assembly appears, and the main components composing it with a green dot when the element is operating, a red dot if the organ is broken. The water level in each tank is indicated, as well as the volume of gray water treated and the volume of make-up drinking water used. The system settings are also accessible directly on the touch screen, but with a password (modifiable).

Communicate regardless of the protocol used:

The box has an RS 485 type link, and can then be adapted as needed (bacnet + ip for example).

Depending on the organization of the BMS, it is also possible to remotely control all the operating parameters, and to modify some of them if a telephone link is made available.

The AQUACLEAR system is a 100% French design product.